Welcome to the New Paradigm in Laser Welding Quality Assurance

Using real-time inline coherent imaging, the IPG laser weld monitoring system consolidates weld results into concise and actionable quality data from a single system that can be shared across shifts and factories around the world. Pre-weld monitoring modes include gap identification, bad fixturing or bad part fit-up before processing begins.

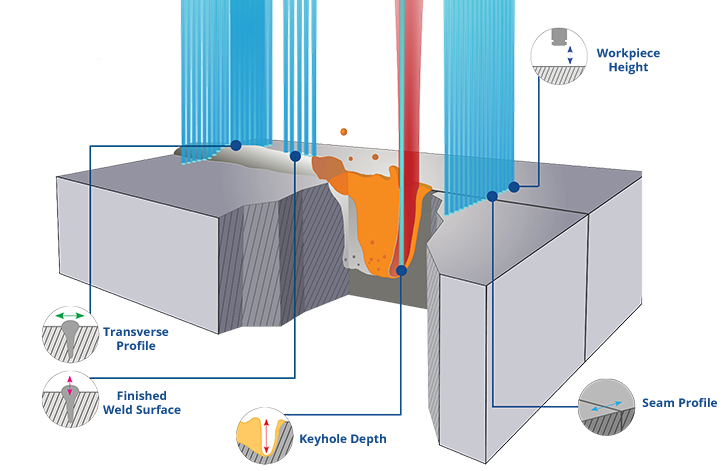

This system also delivers real-time in-weld monitoring at the bottom of the keyhole to record the penetration and fusion depth of the weld for loss of or over-penetration and for process instability. Additionally, post-weld inspection measures properties such as the height of the finished weld surface, the width of the weld bead and the presence of surface defects like pits and blowouts. This IPG weld monitoring solution provides over 20 calibrated measurements of every weld to help improve weld quality, reduce waste and increase productivity.

Join us to learn how streamlining your weld QA procedures allows you to respond immediately to quality issues and ensures that only good parts are shipped to your customers.