Safety Information and Conventions

To ensure the safe operation and

optimal performance of the LightWELD product, follow all warnings in the

product User Guide. Safety precautions must be observed during all phases of

operation, maintenance, and service.

To ensure the safe operation and

optimal performance of the LightWELD product, follow all warnings in the

product User Guide. Safety precautions must be observed during all phases of

operation, maintenance, and service.

Operators must adhere to these recommendations and apply sound laser safety practices at all times. Never open the module. There are no user serviceable parts, equipment or assemblies associated with this product. All internal service and maintenance should only be performed by qualified IPG personnel, except as noted in Section A of the User Guide.

Laser Classification

Governmental standards require that all lasers be classified according to their output power or energy and the laser wavelength.

This device is classified as a high power Class 4 laser instrument under 21 CFR, Subchapter J, part II, 1040.10(d).his product emits invisible laser radiation at or around a wavelength of 1070nm. The total light power radiated from the optical output is greater than 1500W average and >2500W peak per optical output port, depending on the model. Please refer to the product specification for the specific performance characteristics of your device.

This device is classified as a high power Class 4 laser instrument under 21 CFR, Subchapter J, part II, 1040.10(d).his product emits invisible laser radiation at or around a wavelength of 1070nm. The total light power radiated from the optical output is greater than 1500W average and >2500W peak per optical output port, depending on the model. Please refer to the product specification for the specific performance characteristics of your device.

This level of light may cause severe damage to the eye and skin. Due to these risks, a qualified laser safety officer should be present to ensure a safe working environment. Appropriate laser safety protection, guards and procedures shall be in place at all times while the laser is operational.

This level of light may cause severe damage to the eye and skin. Due to these risks, a qualified laser safety officer should be present to ensure a safe working environment. Appropriate laser safety protection, guards and procedures shall be in place at all times while the laser is operational.

This product also contains a guide laser that is Class 2M per IEC 60825-1 and Class 2 per 21CFR 1040.10(g). The guide laser emits visible laser radiation at or around a wavelength range of 600 to 700 nm and is capable of producing a peak power of 1mW. Eye or skin exposure should be avoided. Do not stare into the beam or view directly with optical instruments.

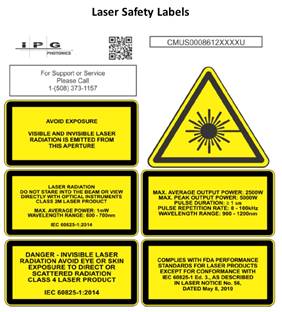

Please refer to the laser safety warning labels in section 2.2.5. of the User Guide

Warning

Class 4 - High Power Lasers present the most serious of all laser hazards. Take precautions to prevent accidental exposure to both direct and reflected beams. Diffuse and specular beam reflections can inflict severe retina and/or cornea injuries leading to permanent eye damage.

Class 4 - High Power Lasers present the most serious of all laser hazards. Take precautions to prevent accidental exposure to both direct and reflected beams. Diffuse and specular beam reflections can inflict severe retina and/or cornea injuries leading to permanent eye damage.

Laser welding systems may create specular reflections due to the interaction of the laser beam and the parts being processed. Highly reflective metals such as aluminum and copper may cause some portion of the beam energy to be reflected from the target weld site and require additional precautions. Specular reflections may also present a hazard to the operator if any portion of the beam is reflected from multiple surfaces. Take precautions to understand the expected cone of specular reflection for each processed part and do not attempt to view the part or place any part of the body within the expected specular reflection cone.

Class 4 laser beams are also a potential fire hazard and skin hazard as well.

When operating the device in the vicinity of others, all personnel must wear appropriate eye protection and take additional precautions to avoid harm from specular reflections. For information on laser safety eyewear, refer to section 2.2.4.

Use of controls, adjustments or performance of procedures other than those set forth in this User Guide may result in exposure to hazardous radiation.

Laser Safety Eyewear

Use appropriate laser safety eyewear when operating this device or in the vicinity of this device while in operation. The selection of appropriate laser safety eyewear requires the end user to accurately identify the range of wavelengths emitted from this product.

Use appropriate laser safety eyewear when operating this device or in the vicinity of this device while in operation. The selection of appropriate laser safety eyewear requires the end user to accurately identify the range of wavelengths emitted from this product.

Please review the safety labeling on the product and verify that the personal protective equipment (i.e. enclosures, viewing windows, or viewports, eyewear, etc.) being utilized is adequate for the output power and wavelength ranges. Decisions on safety eyewear must also take into account any secondary radiation hazards due to the welding process (see section 2.3.1).

Whether the laser is used in a new installation or to retrofit an existing system, the end user is solely responsible for determining the suitability of all personal protective equipment.

There are several laser safety equipment suppliers that offer materials or equipment. Some of them include LaserVision USA, Kentek Corporation and Rockwell Laser Industries. There are other laser personal protective equipment providers. IPG provides the names of these providers solely as a convenience and does not endorse or recommend any of them, or their products or services. IPG assumes no liability for their recommendations, products or services.

![]() Laser safety eyewear must conform to US and international safety standards, including 9 CFR 1926.102(b)(2), ANSI Z136.1 (US) and EN207/EN208 (Europe). The regulations in force will depend on the location of the laser installation.

Laser safety eyewear must conform to US and international safety standards, including 9 CFR 1926.102(b)(2), ANSI Z136.1 (US) and EN207/EN208 (Europe). The regulations in force will depend on the location of the laser installation.

Device Safety Label Locations

The safety label which is affixed on the device, provides information on the laser radiation hazards that are present in your particular device.

The safety label and the information listed on the safety label will vary based on the output power(s), wavelength(s), and other performance characteristics. It is important to review the labels affixed to the product for specific information about your laser device.

This product has the required safety labels located on the outside of the device enclosure at various locations. These include warning labels indicating removable or displaceable protective housings, apertures through which laser radiation is emitted and labels of certification and identification.

Important Welding Specific Safety Information

Secondary Radiation Hazard

Both visible and invisible light radiation will be produced during welding. The interaction between high power laser beams and target materials being welded may create plasmas that produce UV emissions and “blue light” which may cause conjunctivitis, photochemical damage to the retina and/or sunburn like reaction to the skin.

Both visible and invisible light radiation will be produced during welding. The interaction between high power laser beams and target materials being welded may create plasmas that produce UV emissions and “blue light” which may cause conjunctivitis, photochemical damage to the retina and/or sunburn like reaction to the skin.

Welders who are exposed, to invisible UV light without proper protection can suffer permanent eye damage. Even brief exposure to invisible UV light during welding can cause blurred vision, burning, tearing, eye pain and irritation (feeling of sand in your eye).

Protective Eyewear for Welding

Eye protection is required during laser welding to protect your eyes from any reflected or scattered Class 4 laser beams, but also to protect against welding bright light, UV light, heat and sparks.

Eye protection is required during laser welding to protect your eyes from any reflected or scattered Class 4 laser beams, but also to protect against welding bright light, UV light, heat and sparks.

For laser welding, it is not sufficient to wear PPE that only protects against the laser’s IR wavelength. The selection of PPE should also take into account the secondary radiation hazards discussed in section 2.3.1 as well.

EYE HAZARDS DURING WELDING - MANDATORY PPE!

A combination of face shields, helmets, glasses and/or goggles will offer the best protection during laser welding. For example, an additional welding helmet (with appropriate filter lenses) that protects the wearer from UV and visible radiation should also be worn over the laser safety eyewear. A welding helmet can also protect the welder from being injured due to hot splatter, metal particulates and sparks.

A combination of face shields, helmets, glasses and/or goggles will offer the best protection during laser welding. For example, an additional welding helmet (with appropriate filter lenses) that protects the wearer from UV and visible radiation should also be worn over the laser safety eyewear. A welding helmet can also protect the welder from being injured due to hot splatter, metal particulates and sparks.

All personnel working near the laser welding area must also wear laser safety eyewear, a welding helmet, and protective clothing.

Skin Hazard

Exposure to IR and UV light radiation during welding can injure the skin.

Exposure to IR and UV light radiation during welding can injure the skin.

Depending on the intensity of the IR light, skin injuries may include thermal burns or excessive dry skin. Exposure to UV light may cause skin burns that are similar sunburns and will increase a welder’s risk of skin cancer and accelerated signs of skin aging.

Welding sparks may also cause burns.

Laser material processing can transfer a significant amount of energy into a part. Parts may be extremely hot even after the welding process is complete. Ensure that the proper PPE is used to protect against potential burns.

Skin Hazards During Welding – Wear PPE

![]()

![]() Take precautions to prevent

Take precautions to prevent